A friend of mine called and asked me to look at one of his employee’s vehicles. He explained to me that it had already been looked at by two other shops in the area. The issue had been identified to be transmission related, and if he was going to have to spend any money to repair it, he would feel better having me work on the vehicle. Of course, I said “I’ll be happy to take a look at it, when can he bring it by?” he replied “We’ll be up in an hour or so…….. There is no hurry; he has another car to drive”.

Later that day they showed up to drop off the car. It was a 2002 Volkswagen Jetta GLS with 72,000 miles (picture 1). The owner of the car started to explain the concern he was having; “everything was working great, then one day the check engine light came on, and it started to shift real hard and fast. I took it to ———-, and they said it was either the transmission control module or the transmission. They said if it was the module, it was going to be $2000.00; if it was the transmission $5000.00, plus reprogramming and any wire repairs, or it could need both. I paid them $145.00 for looking at it, but I wanted to get a little more specific about what it was going to cost, so I took it to ———. They had it for a week and said they thought it needed a control module, but were not real sure, and asked me to take it somewhere else……… so here I am”. We were eager to accept the challenge and a willing to work on any type of transmission, and since I wanted to be able to find out what exactly was going on with it, I said I would give him a call in a day or so with an estimate for the repair.

I went to road test the vehicle, as well as get some preliminary information, and in a short while I was able to verify the customer’s concerns; the check engine light was on and the vehicle shifted abruptly with a shock at each shift point. I brought the car into the shop and checked for anything obvious; raised it up to see if there were any signs of broken wires or leaks. It all looked good, so I hooked up my scanner and it revealed a DTC P0715 Input / Turbine Speed Sensor “A” Circuit. “Well, this ought to be easy enough” I said to myself, but this was preceded by a comedy of errors that I am embarrassed to talk about; but c’mon, we have all been there at one point or another.

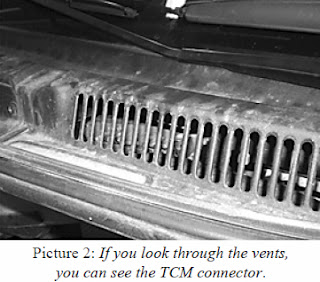

Realizing it was a newer transmission, and probably not a lot of technicians have worked on the VW O9A before, it was going to be diffi cult to fi nd an accurate diagnostic procedure. To make matters worse, there is an ‘early’ and a ‘late’ design of this model transmission. I was amazed at the amount of information one can find on the internet as well as the various subscription services, along with having a very reputable V.W. Dealership in our town; so what could go wrong? I printed off the wire diagram from our subscribed website to get an idea of what I was in for and to be honest it seemed pretty cut and dry. Pin 9 and 10 were the signal wires coming out of the transmission going to pin 09 and 36 at the TCM, which is located under the plenum that covers the wiper motor, (picture 2 and to me that seems like a good spot for water intrusion). The wires were good, and the TCM appeared to be dry, so after about two hours of chasing wires, and taking stuff apart I am to the point of it either needing a module, or the transmission needs to come out.

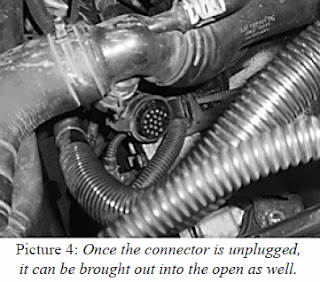

Knowing I could not call the customer and tell him the same thing the other shop just told him, we decided to take the diagnostics to the next level. I simply raised the car up a bit, put it in drive to let the wheels start spinning, back probed the wires going to the TCM, and found there was no signal coming out of the transmission. I turned the car off, unplugged the transmission, probed the wires going to the ISS9 (Picture 3 and 4), and needless to say the sensor was way out of range and needed to be replaced. I called around to see if the part was available from any source other than the dealer, and it was not. While on the phone with the VW parts department, I asked about the history of the part (in an effort to ensure I was on the right track), “We have never sold one here, most likely because it is an internal part and we would simply replace the transmission, rather than try and repair it… the part is $148.00 and the transmission is $4815.00, I can have either one for you in two days” was the reply I got. Not quite the “OH YEAH … Sell tons of them, in fact we have 4 in stock” I was hoping for: however, I confidently ordered the part, and asked them to fax a picture of the sensor. Fig 244 of Mitchell on Demand was the picture on the fax machine; #2 is ISS #1 IS OSS

Now I had a picture of where the part was located, and the part was on the way. I called the customer and told him what I had found and provided him an estimate for the repair, and while it was unfortunate that is was 11.5 hours labor to replace the part, we were a long way from $5000.00 for replacing the transmission. The repairs were authorized, and the part was a few days away, and our shop started to get busy, so I told him it would be late next week before I could work on it again. With that I moved on to the other cars in the shop.

The part arrived on Thursday morning, with the mental picture burned into my memory from the fax received a few days before, I knew I had to remove the transmission, separate the case and replace the speed sensor just under the pump assembly, bolt the case halves back together and reinstall the transmission, the shop was very busy so it was clear that I would not be able to get on it until late Friday or first thing Monday. My plan was to bring the car in on Friday afternoon and get it ready for repairs on Monday; I took the tires off and drained the fluids, which didn’t look too bad.

Monday; got the transmission out ‘ok’ and slid it onto the bench. It looked like the cases were sealed with sealant, so there should be no other parts needed. I separated the cases and there it was, just like the picture I studied. The shop was still very busy, so I decided to replace the sensor, bolt the cases back together, and I would reinstall it after we slowed up a bit; I did tell him late next week after all. I opened the new speed sensor, it matched up perfectly to the one I was replacing, no other checks needed; two bolts and one plug in and I’m done, so I bolted the cases together with assembly adhesive flipped it over, and went on to the next job.

We managed to get back to the install late Wednesday, I got it all wrapped up with $85.00 worth of fluid pumped into it around closing time, ran it on the rack, checked the fluid, shut the hood and did the final road test the next morning, only to reveal the same concern we started with, the check engine light came on, it shifted quick and hard by the time I got out of the parking lot. I ran it back in the shop, and the scanner showed DTC P0715 Input/Turbine Speed Sensor “A” Circuit. “Where the hell did I go wrong here?” I said to myself.

Trying to regain confidence in my diagnosis, I came to the conclusion “Of course! The dealer is the only one that can clear this code, I don’t have a VAG! The code must still be stored in the TCM and I can’t clear it” I jumped in the car and drove it to the local dealer; luckily the tech was available for a quick check of the car. We hooked it up to the VAG and it displayed code 17099 Input/Turbine Speed Sensor “A” Circuit, (things are looking up now!) We ran through the same tests I performed a week earlier, and came up with the same results, an open ISS;“I just put a new one in, bought it here as a matter of fact”, he replied (just like I was thinking) “must of got a bad one” and back to the shop I go.

Reluctantly I pulled the transmission back out of the car, slid it onto the bench, separated the cases and placed the faxed picture alongside the sensors to make sure I changed the correct speed sensor, sure enough; it should have worked, but it didn’t. After conferring with our resident electrical expert/service advisor Jerry Temmen, it was determined there is either a bad speed sensor or a bad wire going to the speed sensor OR the wrong picture of the speed sensors in the transmission.

PRSRT STD U.S. POSTAGE PA I D FORT DODGE, IA

PERMIT NO. 733

To make a long story short, the picture that was faxed to us, along with the picture we printed off of our online subscription were of a different version of the same transmission. What the picture shows as the Input Speed Sensor and the Output Speed Sensor, is actually a picture of the Output Speed Sensor and the Intermediate Shaft Speed Sensor. I replaced the Intermediate Shaft Speed Sensor, not the Input Speed Sensor as I had thought. The input speed sensor actually picks up its signal from the K2/K3 (high clutch/reverse clutch) drum at the back of the transmission. In any event, I switched the sensors, put the transmission back in the car, and shipped the vehicle.

Where I went wrong was stopping the diagnosis based on pictures and visually identifying the parts assuming the concern was isolated. If I would have spent five minutes checking the continuity between terminal 9 and 10 to the (what I thought was) the input speed sensor, it would have read OL, that would have led me to checking the rest of the wires, and eventually finding the correct speed sensor to replace. In other words, I would have gained the ability to verify the correction prior to me reinstalling the transmission, and would have saved a lot more time than me trying to shortcut the procedure so I could continue working on other cars in the shop.