Huh? NV4500 manual transmission fails in the field because of a hydraulic issue? You’re probably saying to yourself “This guys wacked or drinking his lunch if you know what I mean.” There’s nothing hydraulic about a NV4500 5spd manual transmission.

This all starts with a 2002 GMC 2500 with a complaint of sticks in fifth gear. Customer states that this has happened to him half a dozen times since the transmission was installed 2000 miles ago and to make matters worse the technician at our shop couldnot duplicate the complaint.

This struck me as very odd complaint for this type of transmission. Over the years there has been a lot issues with fifth gear and the nut that retains it on the shaft but I do not recall that it ever made the transmission stuck in fifth. No fifth, pops out fifth, hard to engage reverse; these are typical complaints of this unit.

Another big complaint of these units is leaks due to cracked cases, extension housings and 4 x 4 adapter housings.

Needless to say after removing the transmission and disassembling fifth and reverse assembly and the shifter tower inspecting them very closely with a fine tooth comb, everything looks really good. At that point I chose to replace fifth gear and the synchronizer assembly. I did a little dance over it, got out the holy water, knocked on wood and crossed my fingers.

I put it back into the truck drove it several miles with no problems and returned it back to the customer. After all, this unit was shifted in and out fifth a hundred times or so on the bench before and after assembly with no problem. It didn’t fix it but I did get a better description of the complaint this time.

Customer said: “After driving in fifth for more than a mile, the transmission is hard to shift out fifth gear”. Now what? To compound the problem, this unit was what we call a stock unit. A transmission we had on the shelf already built. We didn’t know What was wrong with the original unit before it was remanufactured and shelved?

The only real history I have on the unit is a list of the parts we put in it originally and I saw nothing unusual there.

So in desperation I took one more look at the list of parts put in this unit and the only thing that I have not looked at that might play into this is that the case was changed.

At this point, I locate a core unit of the same type and disassemble both units side by side for comparison. It didn’t take long before I realized that the two units were different and why they were different.

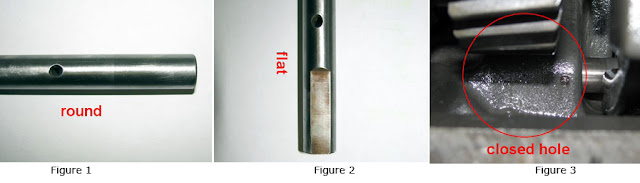

The fifth and reverse shift rails in the case were different. The rail that goes in first (towards the front of the transmission) in the unit in question was completely round (see figure 1) and the one out of the core (see figure 2) had a flat spot machined down the side. The case had a blind hole (see figure 3), so when the unit was full of fluid in the vehicle driving in fifth gear for a long period of time oil would slosh up around the shift rail and hole. It then would eventually fill that void between the case and rail so when you went to remove the shifter from fifth it would hydraulic lock in the case.

You would have pull on the shifter and bleed that oil back threw the clearance between the case and rail. Needless to say, now I know what that flat relief is for in the other rail and why you can shift it flawlessly with no fluid in it. Turns out some cases (see figure 4) earlier ones are open and the round pin works just fine. Don’t make the mistake of installing the round pin into a blind hole case or it is possible to have a hydraulic failure of a manual transmission.